A G Ivchenko developed the AI 14 engine in 1948 as a standard engine for all Russian light aircraft, producing 260 hp. In the early 1950s, Ivchenko began work on turbo-prop engines, and in their wisdom the Russian authorities decided to allow him to concentrate on turbine engines and then gave the basic AI 14 design to four different engine manufacturers. From the early 1960s, part of the original design bureau, based in Voronezh, Russia, came under the control of I M Vedeneev, and he undertook a significant redesign of the AI 14 in order to produce more power and developed the M 14 P engine of 360 hp. Although the basic engine was very similar, it was significantly strengthened to develop more power – for example the M 14 has six satellite gears in the gearbox, whereas the AI 14 has only three.

The basic AI 14 design was given to PZL in Poland, who made no significant changes and continued to produce the engine for many years, and of course it was the standard engine in the Wilga. The AI 14 design was also given to LOM in Czechoslovakia who again made various modifications to produce the M462 engine of 305 hp and used in the Zlin crop-spraying aircraft. Finally, the design was also given to the Chinese, together with the design of the Yak 18 A military training aircraft – of course the predecessor to the Yak 52. The Chinese decided to completely redesign the aircraft to produce the Nanchang CJ-6, but did very little to change the engine for their use, now called the HS-6.

M-14 family of engines and our capabilities

The M14 series of engines is recognised as being one of the finest light aircraft engines of all times. They are:

- Extremely lightweight for their power.

- Very tough and reliable – the Russians operate generating sets in Siberian oil fields powered by M14Ps, which are expected to run for 20,000 hours before overhaul.

- Fully ‘inverted’ with the ability to run in any attitude.

- Dry-sumped, which ensures good lubrication at any attitude.

- Economical, despite their power – as little as 40 litres of fuel per hour at economical cruising.

- Currently the most powerful light aircraft engines available today – in versions up to 450hp.

- Beautifully made incorporating such items as roller cam-followers and roller-rocker arms.

We are undoubtedly the world leaders in the sale of these engines, both new and overhauled. Over the last thirty years, we have sold more than four hundred engines to customers all over the world, indeed, even back to Russia. The last new engine from Russia was manufactured in 1993/4, although small amounts of engines have been made subsequently from unused, old-stock parts, but increasingly more and more overhauled parts have been incorporated, but our view is that there are no ‘new’ engines that have been made for the last fifteen years, and, almost certainly for the future. Having said that small amounts of the large Russian historic production was distributed throughout Russia, and bought by people such as ourselves and then sold on, so there is still a certain number of unused, but old stock engines available. In terms of these engines, we would point out that the initial conservation was good for six years, and then extended for ten. Beyond this it is prudent to remove cylinders; check the engine internally; reassemble and re-conserve. An interesting read is ‘An Introduction to the MP14P for flat-engined pilots’ by Fred Abramson.

OKBM – Vedeneyev

The principal product of the Vedeneyev Design Bureau has been the M14 family of engines, originally designed as the AI-14 by the Ivchenko Design Bureau at Zaparozhye in the Ukraine.

Vedeneyev’s first engine was the AI-14RF, which produced 300hp and this in turn led to the M14P, which was introduced in its Series I form in the early 1970s. This produced 360hp, and Series II came out in the early 1980s, still delivering 360hp, but with a variety of small internal improvements.

Under the Soviet system (above) the actual manufacture of these piston engines was given to the Voronezh Mechanical Plant (VMP) a huge State controlled organisation, also in Voronezh , making a variety of aerospace products, including the Buran space-shuttle.

After the collapse of the Soviet Union the lavish funding which Vedeneyev (also known as OKBM) and VMP previously received stopped, as did the requirement for large numbers of engines. This made little difference to VMP, for whom the production of piston aircraft engines was a relatively small part of their business, but created a significant problem for Vedeneyev, for whom the design of engines represented approximately half their business – the remainder being aerospace gearboxes. It is fair to say that we kept the business afloat during these difficult times with overhaul and spare parts business.

There was continuing large scale production of engines in the early 90s with the last completed engine being manufactured by VMP in 1994. However they still had large numbers of major components and have continued to produce small numbers of engines since then from these pre-existing components and sub-assemblies.

It seems that all activity at Vedeneyev has now stopped.

The Romanian involvement

Under Soviet agreements, Aerostar in Romania was designated as the production plant for Yak-52 aircraft and their sister company Aeromotors (now called Motorstar) was given license to produce M14P engines for these aircraft. It is difficult to be sure, but it would seem to us that most Yak-52s were made for the Russian Air Force/DOSAAF in Russia and that the vast majority of these aircraft were fitted with Voronezh M14P engines from VMP, which were shipped to Romania for installation. However Yak-52s for other customers outside Russia usually have Romanian-built engines.

Enhancing the performance of the M14P engine and the development of the M14PF

The M14P family is certainly one of the World’s legendary aircraft engines, to a certain extent because of its exceptional record in world-class aerobatic competitions, but also because of its charismatic noise and high-power output for its weight. As the only radial engine in recent production, it also has a great deal of historical interest. The Russian National Team began asking for more power and the result was the M14PF in which the power is increased to 400hp by changing the supercharger drive gearbox so that the supercharger is turned at 10.5 times engine speed rather than 8.25. This therefore uses the same supercharger and other systems, but turns the supercharger impeller at an extremely high 30,000 rpm in order to produce the higher levels of boost necessary for greater power. The PF engine is now well-proven after some 30 years in service. In- service testing was done with the Russian National Team and the engine was principally used in competition aircraft, such as the Sukhoi, but now has much wider application in other Yaks. We have now sold more than 100 ‘PF’ engines to customers all over the world and they are being fitted to all Yaks types, both to achieve higher performance for aerobatic aircraft, but over 60% of the Yak-18Ts we sold were fitted with ‘PF’ engines to enhance take-off and climb performance as well as high altitude cruise. We have found PFs to be very reliable in practice, indeed on a statistical basis, somewhat more so than standard M14Ps. In the USA where engines can be operated ‘on condition’ several PFs are well over 1,500 hours with many over 500 hours.

The requirement for 450hp

The Russian Air Force issued a requirement for a high-performance two-seater training aircraft powered by a piston engine, to take over from the Yak-52. Sukhoi proposed the Su-49 – a tricycle retractable and extraction-system equipped version of the Su-29. Yakovlev proposed the Yak-54M, a similar modification to the Yak-54 aerobatic aircraft. In both cases the requirement was for a 450hp engine given the greater weight of the aircraft. The potential engine requirement was going to be large and clearly of interest to both Vedeneyev/OKMB and VMP.

The requirement for more power in sport aircraft

In 2002 we could see that there was a real market for an engine that changed a single seat Sukhoi from having a power-to-ratio of just under 1 to over 1, which could totally transform the aerobatics that were possible. We discussed this with Vedeneyev, and over a two year period, with our funding, they developed the M14R, essentially an M14P gearbox and crankcase, but with a totally re-designed supercharger and accessory case section. We had initially intended to use fuel injection, but for a variety of reasons well over 450hp was available with a carburettor, which meant that this was not necessary. Also it was felt that the engine would not be considered for use by the Russian Air Force if a non-Russian fuel-injection unit was used and at that stage there were no suitable Russian versions available.

The M14R in service

We sold a number of M14R engines, although the first 3 engines suffered identical failures in the bushings of the supercharger drive shafts, which were turning at much higher speeds and under greater load. In all cases the engine continued to run and the aircraft landed safely. However this led to a re-design of the defective bearings, which were changed from bushings to roller bearings and after significant amounts of testing, the engine was put back in production, albeit slowly. We put as much pressure on Vedeneyev as possible, since we had considerable demand for these engines. The capability of the M14R engine is demonstrated by the fact that overall victor of the 2007 World Aerobatic Championships was Ramon Alonso of Spain flying his M14R equipped Sukhoi Su-31 aircraft – there can be no tougher test of an engine.

M9F engine

VMP began looking at ways of achieving the requirements for the Sukhoi Su-49 and for political reasons a bond had already been established between VMP and Sukhoi for this engine. A major problem was that the Su-49 has hydraulic rather than pneumatic systems and therefore the engine has to have a hydraulic pump as part of its ancillaries. Vedeneyev/OKBM had previously developed an engine called the M14B (360hp) for the Antonov An-14 ( a small utility aircraft), which had been totally re-designed to accommodate a hydraulic pump behind the supercharger. VMP decided that this engine should be the basis of their higher power engine, which they called the M9F, indicating that it is radically different from both the M14B and indeed the M14P. Inevitably, with two design teams working towards the same goal their results have been similar, although very different in detail. Indeed, we have bought/sold/overhauled a number of M14B engines and, although superficially very similar to M14P, it is interesting how many detailed differences there are. In 2003 Sukhoi decided to upgrade the Su-26M into the Su-26M3 and this aircraft was fitted with the M9F engine. This combination of engine and airframe won almost every world and European Championship for several years. We had an exclusive arrangement with VMP for the supply of M9F engines, and have done all we can to get regular supplies. However VMP received, in the middle of 2007, an order for 120 new M14P engines, principally for 60 new Yak-18T aircraft for the Russian Ministry of Transport. This has meant that their energies were totally directed to this big contract and we doubt whether more M9F engines might be available. However we have sold a number of them; one powered an American-owned Su-26M which won the Freestyle gold medal at the 2007 World Championships – certainly the most demanding element of the championships. The requirement for the Su-49 was 450hp and it was intended to achieve this with the M9F with fuel injection becoming the M9FS.

Exchange PF supercharger assemblies

With this procedure we sell the entire rear of the engine – that is everything behind the crank case including all of the ‘PF’ conversion kit built into the supercharger and all ancillary drives. This conversion is a straight ‘bolt-on’ conversion, although the engine needs to be removed from the aircraft and all accessories (magnetos, carburettor, oil pump etc) need to be removed. Finally the carburettor needs to be readjusted to cope with the different mixture requirements of the PF. Please contact us for more details.

Our plans for the M14R engine

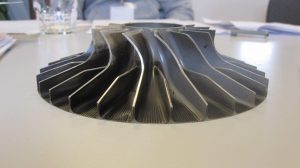

M14P impeller

As we have written elsewhere, we were closely involved with Vedeneyev in the design of the M 14 R engine, and indeed sold a small number of them, but they had problems, and the project was discontinued. At the time we concentrated on the design of the supercharger which of course goes back some 70 years, and it was clear that the simple technology of the impeller with almost single-plane vanes was very inefficient. Through the good relationships that Sukhoi had with Lyulka, who of course make the engines for the big Sukhoi fighters, we asked them to redesign the impeller and diffuser. They designed much more complex multi-curvature vanes and corresponding diffuser. Then the gearing of the supercharger, normally 8.2:1 in the M 14 P, but rising to 10.4:1 for the M 14 PF further increased to 11.5:1. On the test bed the engine was extremely effective, delivering a corrected dynamometer reading in excess of 475 hp. So we began delivering this engine, but the whole project had been somewhat rushed and insufficient thought had been given to the power required to turn this impeller at well over 30,000 rpm with its much higher boost pressure. The result was that we kept having failures of the supercharger drive. Fortunately this did not mean that the engine stopped – but simply operated without boost, but quite expensive for us in repairing these engines, and in the end we decided to discontinue the program. But in the meantime it won the World Aerobatic Championship in the Sukhoi 31 of Ramon Alonso.

M14R impeller (left) & M14P impeller

More recently, working with Aerometal, our partner in Hungary, we have decided to resuscitate the M 14 R. We obtained an engine that had done over 200 hours perfectly successfully in a Yak 50, owned by a customer who felt it appropriate, given its hard used to have it overhauled. Aerometal very carefully examined all aspects of the supercharger drive; could see which parts were insufficiently strong for the new supercharger. In addition there were various aspects of the supercharger drive where we felt that there was insufficient lubrication in this more demanding environment.

M14R impeller

So all the work has been done, but it’ll be a major task to put everything into practice, needing to design new shafts; gear wheels; lubrication system et cetera, and at a time when we are extremely busy with conventional engine overhauls et cetera. However it will be done, and will be selling complete M 14 R engines after extensive testing. We will be aiming at a dynamometer-corrected 480hp, which we know from Vedeneyev is within the capabilities and strength of the basic engine. Inevitably they will not be cheap, but the performance will be worth it!

Exchange gearboxes

The original M14P has output shaft with radial splines to mate with corresponding splines on the Russian V-530 propeller. Most PF engines have been intended for use with the German MTV-3 and MTV-9 propellers and so have been delivered with American SAE flanges. However, MT now makes propellers with both Russian and Western flanges, so effectively these are interchangeable. We can supply fully overhauled gearboxes incorporating either flange.

Electric Start

For those interested we can also offer conversion of M14P to electric start rather than air start.

Overhauls

Please see the separate description of our engine overhaul business.

Our overhauled engines come from our partner, Aerometal in Hungary, who are the oldest established and largest overhauler of the AI-14, M14 and HS-6 families of engines in the world.

Our current pricing for engines

Our current pricing for engines is under Engines for Sale

Plug Conversion Kits

We have European exclusivity for the installation of the superb automotive plug conversions, and have EASA and CAA approval for this for all aircraft with these engines on both Sukhoi and Yak aircraft. A weakness of the Russian high tension ignition is that it uses relatively thin wires forced into a metal conduit and over time the insulation tends to deteriorate allowing cross sparking between wires. Also, the Russian sparking plugs are very ‘old technology’ having been designed some 50 years ago. The Automotive plug conversion uses racing car-type silicone leads and the latest type of sparking plugs. These provide easier sparking; cooler running; slightly greater power and are the best conversion one can do on these engines for the money.

High compression pistons from Carillo (USA)

These start with a completely different piston “blank”, from American racing car technology, which expands at almost exactly the same rate as the cylinders, so cold clearance can be very tight, while still having sufficient clearance when hot. This leads to considerable advantages:

- Oil consumption is approximately 20% of standard pistons.

- Oil remains clean.

- There is significantly less “plug-fouling”.

- The engine has less piston friction so it gives a bit more power and runs cooler.

These pistons have been tested at length, both on test-beds and in very arduous use in air-show Sukhois and other aircraft. They are available in either the standard compression or a higher compression version (8.4:1). The latter, when installed in the M14PF, will typically give an increase of around 25hp in itself. So an engine thus equipped will typically give 450hp, together with all the various other advantages above.

SPC pistons from Motorstar in Romania

Motorstar continue to make the M14P in small quantities, and were of course the manufacturer of a large number of M14Ps for the Yak-52s manufactured by Aerostar, their sister company next door. They have been working on the same problem, and have developed the SPC piston, which has now been in use for several years. This uses the same Russian “blank”, so does have the same disadvantages of the high rate of expansion. BUT it has much better technology piston -rings, and utilises only three piston rings rather than five. So this means that oil consumption is typically reduced by 40%; the engines run cooler and give slightly more power. Importantly, because the original blank is the same, we can manufacture engines using SPC pistons. So, according to customer requirements we can fit either Carillo or SPC pistons, and we are delighted to discuss particular requirements for any specific application.