Engine overhauls from RGA and Aerometal

M14PF with Barrett pistons and electronic ignition, to the USA for a Sukhoi

The involvement in these engines from RGA goes back to 1986 when we brought the first Yaks to the West, and of course soon became involved in engine and engine related issues. Over a period of time we found that the principal Russian factories –Vedenyev who designed the engines and the Voronezh Mechanical Plant who actually manufactured the engines – were becoming more and more unreliable and difficult to deal with. Fortuitously, some 16 years ago, we were introduced to Aerometal at Soskut, near Budapest.

The parent company of Aerometal was established in 1959, with an initial emphasis being on the overhaul of the M14V engines for the Kamov 26 helicopters which were in wide use in Hungary in crop-spraying. Now that all the original Russian overhaul factories have effectively disappeared, Aerometal is now significantly the largest and oldest-established business in this world of these Russian radial engines. When Hungary joined the EU, the crop spraying activities were investigated by EU agricultural specialists, who were unhappy about the sorts of Soviet chemicals that were being used, and stopped much of the business. We came to an agreement with Aerometal to replace all their helicopter engine business with fixed wing engine business, and this relationship has continued extremely successfully.

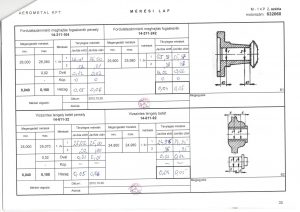

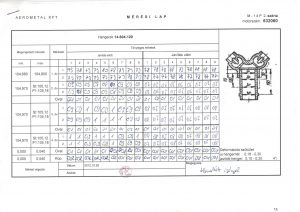

As one of very few companies in Eastern Europe who were authorised to perform total overhauls to zero-time condition on these engines, Aerometal have all original Russian archive material – for example over 2000 pages just for the M 14 P. These list every facet of the overhaul procedure, and also all dimensional requirements for every single part and component. At the bottom of this page you can see two sample pages (out of 162) covering every aspect of the engine analysis, indicating the dimensions that need to be measured and the tolerances that are allowed.

Our business today

M14PF with 455hp, our most powerful engine to date! For “Super Wilga” in USA

RGA handles all the commercial activities for Aerometal, with the exception of their historic M 14 V helicopter business. This works extremely well, since it leaves Aerometal free to concentrate on all the technical issues. We are sure that our engines are significantly the best in the world, for a variety of reasons:

- As you will have read above they are the oldest established, and also significantly the largest business in this world of these Russian engines and their successors. The combined experience of their specialist technicians is over 120 years – unmatched anywhere else.

- Aerometal is a self-contained business, and in addition to the engine workshops, they also have a very sophisticated machine shop; a fabrication area; an anodising and plating workshop and a painting facility. In effect, all work is done in-house.

- Aerometal is the only company in the world who are fully authorised by EASA (who control all aviation issues within Europe) to overhaul these engines.

- Every part of the engine is totally overhauled, including all ancillaries, and even including the engine mounting ring.

- Aerometal have massive stocks of new spare parts which have been deliberately built up over the years, so do not have to resort to “making do” with somewhat worn parts.

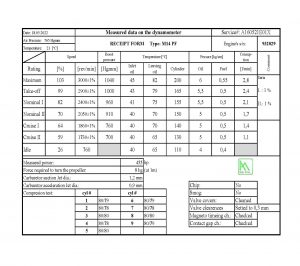

- Each engine is assembled by one very skilled specialist, rather than on a production-line basis with semi-skilled operatives as was the case in original manufacture in Russia. This means that the engines can be assembled with significantly tighter tolerances than originally specified in the documentation, particularly in the supercharger and valves, and in turn this results in our engines developing at least an additional 25 hp over the nominal output for that type of engine. Importantly all our engines are tested on a precise dynamometer which is calibrated for an accuracy of 0.1% and the actual results of each engine are given to the customer of that engine. Each engine is tested for a minimum of three hours.

- We automatically replace around 150 parts where replacement is considered to be mandatory.

- Whereas other overhaulers of these engines will typically only install new piston rings, we always insist on fitting complete new pistons, and of course this includes new piston rings; piston pins and piston plugs. We fit the latest SPC pistons which have three high-technology piston rings rather than the five heavy and low-technology standard rings. These result in oil consumption being reduced by approximately 50%; less plug-fouling; more power; cooler running.

- We can also provide the excellent American Carillo pistons, which are made from a completely new aluminium which expands at precisely the same rate as the cylinders, so it can be made with a tight fit when cold but ensuring no problem when hot. These reduce oil consumption to approximately 1 L in 3 hours; the engine runs cooler; they virtually eliminate plug-fouling; give easier starting and are available in a high compression version, which adds a typical 25 hp to an engine’s output.

- Each engine is balanced to a factor that is three times as good as specified in the original Russian documentation.

M14PF with automotive plug conversion kit and Carillo pistons, for SU-31 in Ireland

- We place considerable emphasis on engines that are finished to a lovely cosmetic standard. The principal parts of the engine are finished in the colour of the customer’s choice, and all exposed metal parts are either plated or anodised. Indeed there is a possibility to “colour-match” some of the anodised parts if a customer wishes.

- We include our excellent automotive spark-plug conversion kit, our new AYC coils, and for both we have obtained full EASA certification, with each engine.

- Engines are fully conserved before leaving Aerometal.

- With each engine we supply additional suction jets for the carburettor so it can be precisely “tuned” after installation.

- We give and stand by a generous warranty on each engine that we supply

We genuinely believe that our engines from Aerometal are not only the best in the World, but significantly better than when they were in new production!

Complete engines and overhauls

Our business is split into three areas – the overhaul of engines for customers; the supply of totally zero-timed engines for the growing market of constructors building aircraft using engines in the M 14 family, and the supply of fully overhauled engine ancillaries and parts.

We have large stocks of engines (over 60) which are waiting for overhaul, which enables us to accept an order for future delivery; prepare the precise engine that is needed; deliver the engine, and then receive the customer’s old engine when it has been removed.

Engine modifications

Sectioned M14V engine, for display

Our engines are assembled to significantly improved standards in various ways, but there are also alternatives in terms of specification:

- A choice of Russian or SAE propeller shafts – we supply either at the same price.

- Cosmetic alternatives, as above.

- Installation of “PF” superchargers, the original Russian design of which was funded by us, and which we feel are a distinct advantage, purely apart from the additional 40 hp that they give.

- Installation of high-compression pistons.

- Provision of electric-start engines – which are increasingly popular, although historically, all these engines would operate with air-start.

We are able to provide a complete range of engines from a standard AI 14 RA engine, which from us typically gives just over 285 hp, up to an M 14 PF with special assembly; AYC coils; our automotive plug-conversion kit and high-compression Carillo pistons with which we will guarantee 450 dynamometer-tested horse power and excellent reliability.

Micropolishing of gears

Two gearbox satellite gears. The one on the left has been micropolished

Micro-polishing is a specialised treatment of gears in which the surface of the gear is very carefully polished in the areas that it is meshing with another gear which can significantly reduce friction, and therefore release more power and reduce oil temperatures. We did extensive research on this, working with the well-known UK producer of automotive competition gearboxes, Hewland, and decided that there were thirteen specific gears which would benefit from this treatment.

The gears we micropolish. The pen is for scale.

The most important are the six satellite gears in the drive gearbox and the associated ring gear. In addition, we also micropolish the six gears in the accessory and supercharger drives. We estimate that micropolishing will produce an additional 7/9 hp, and reduce oil temperature by 7/10°C.

Data plates

All new engines have new appropriate data plates, obviously with correct and original serial number.

Reviews from some very satisfied engine customers:

- “I bought an engine from Richard Goode for our aircraft and we fitted it up last year. It was AWESOME right from the offset and the purchase process was exceptional… Absolutely top service. I cannot speak more highly of my experiences with purchasing one of their ‘Ultimate’ Engines and would highly recommend them to anybody.” Chris Bradbury, M14PF

- “I flew Gillespie, CA to Kingman. AZ for a formation clinic and back home last Oct. Nine hours total on an engine from Richard Goode and only used 1qt. oil!!! What a treat!” Todd Bohlman, M14P

- “Quick acceleration and raw power…blown away by the performance.” “ All I can say is WOW! This engine is smooth and super responsive.” Bill Mills, HS-6

- “It starts unbelievably easy and is so smooth… I cannot thank you and Aerometal enough for an outstanding product and the communications we have shared throughout the process. I am looking forward to many years of happy flying with the new and improved engine. Keep up the great work.” Greg Wrobel, HS-6

- “A beautiful Aerometal Housai… I’m so impressed with the quality of their work. Engine started right up and performed flawlessly on the ground. The first flight came back with zero engine discrepancies” Jason Berman, HS-6

- “Very pleased with the power and performance” Brian Youmans, HS-6

- “The new engine is fantastic! Many thanks for that. I am taking advantage of this extra power” Markus Breuer, M14PF

- “Runs great, nice and dry, climbs like crazy. 500 FPM more initial climb rate, 10 more Kts cruise at same fuel burn, 7 hours so far and no perceptible oil consumption. All at stock RPM.” Andrew Wait, HS-6

- “Your engine is a piece of art and is what swayed me to purchase this CJ over others.” Jeff Greenwood, HS-6

- “I’m already doing the second annual on the engine. It’s running great.” Jon Boede, M14P

Pricing

Please see “Engines for Sale” for our prices.

Overhauls are priced according to the engine, but essentially cover every aspect of the overhaul, with the exception of any parts that might be damaged through overheating; hydraulic lock or whatever.

We are also able to supply, typically on an exchange basis, all ancillary parts, all completely overhauled, such as magnetos; carburetors; governors; compressors; fuel and oil pumps et cetera. In addition we supply complete “PF” supercharger and accessory case conversions which can be simply fitted to an existing engine. Please see our Parts page for our latest Parts Price List.

Our procedures

The principal stages that an engine go through are:

- An acceptance report on engine arrival, which is typically done within three days, which will describe the engine; any missing parts or other obvious problems.

- Total disassembly, followed by removal of all paint and complete cleaning of every component.

- Testing and examination of every component, whether by measuring; x-ray; crack-testing to check for those that should be rejected or retained. You can see below two sample pages of the 121 pages, showing the actual dimensions established during examination of an actual engine, against the required dimensions.

HS-6 with Carillo pistons

- Sourcing of all new parts and components that will be required.

- Detailed processes such as honing the cylinders; grinding the valves; manufacture of new bushings et cetera. All this is done in-house.

- Painting of all components in the appropriate colour; plating or anodising of other parts, again in-house.

- Assembly of the entire engine.

- Testing on the dynamometer with recording all results, which are given to our customers.

- Rechecking valve clearances; magneto timing et cetera.

- Conservation and then packing. For airfreight we have developed our own lightweight, but strong, crates which are also made from treated wood, and therefore are acceptable to the authorities in countries like such as USA and Australia.

- We have excellent contacts and are able to ship engines by road within Europe and by air anywhere in the world.

One sample page from 121 pages that cover all aspects of the engine analysis

An example page showing the actual dimensions established during examination of an actual engine, against the required dimensions

A sample test result page, for M14PF 932029, to be fitted to a Yak-18T in Germany